#92 Smartex

AI eliminating textile waste

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we'll distill a company that's using AI-powered cameras to detect textile defects in real time, stopping waste before it happens: Smartex 🇵🇹

Do you use Google Drive and love color coding to stay organized? 🎨

If so, check out this extension I built that lets you customize any folder with UNLIMITED colors. 👀

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Smartex Tackle❓

They tackle inefficiencies and defects in textile manufacturing, leading to high waste and economic losses.

1. Massive Defect Waste: Over 5% of global textile production is lost every year due to irreversible fabric faults. A $33 billion annual loss. A single machine problem can ruin thousands of meters of fabric before anyone notices.

2. Stone-Age Inspection: In a $3 trillion industry, quality control is still done by human eyes. Manual inspection only catches about 70% of defects, meaning nearly a third slip through.

3. Environmental Impact: The fashion industry produces 10% of global carbon emissions and 20% of global water waste. When defective rolls go undetected, they get discarded or burned, wasting all the resources that went into making them. 92 million tonnes of textile waste are generated every year.

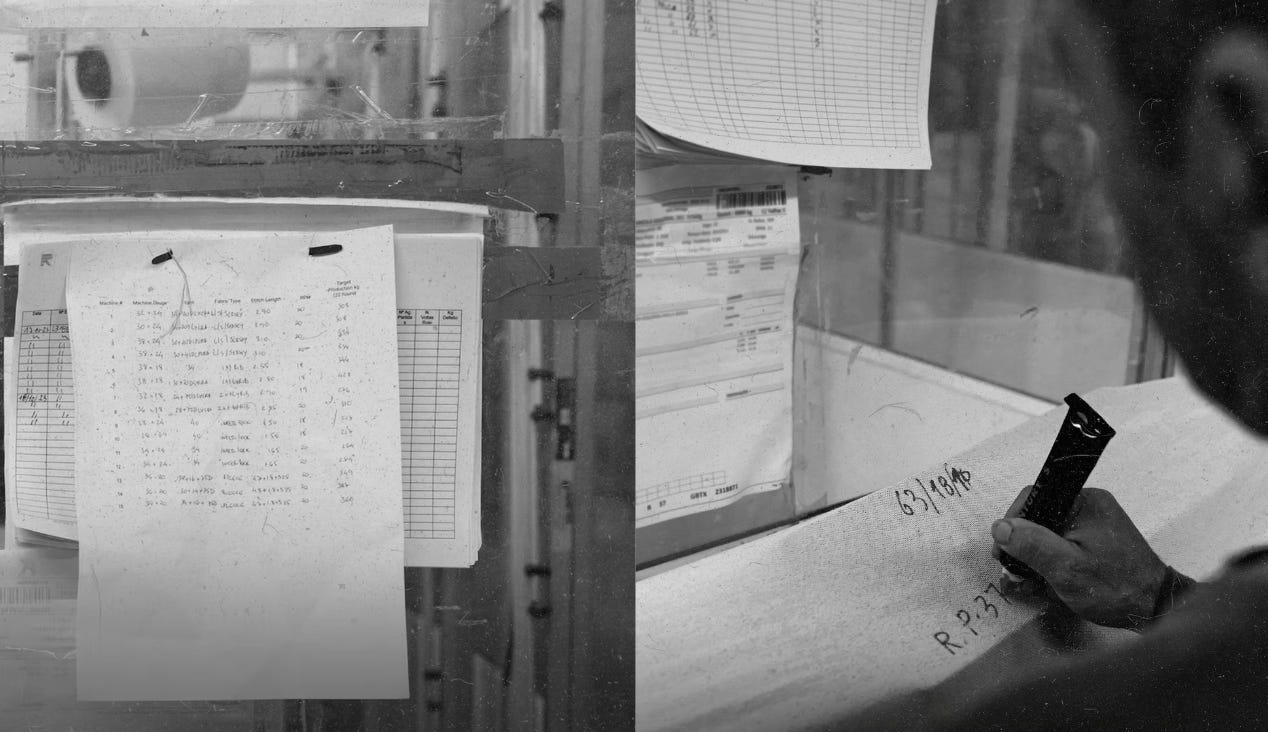

4. Zero Digitalization: Most factories still run on paper production orders with no real-time data, no traceability, and no way to share quality info with brands. It's probably the largest industry still untouched by the internet.

5. Insane Scale: 150 billion garments are produced annually. Even a tiny defect percentage at that scale means staggering waste, and fast fashion is only accelerating the problem.

The industry desperately needs digital eyes inside its factories.

Product / Service 📦

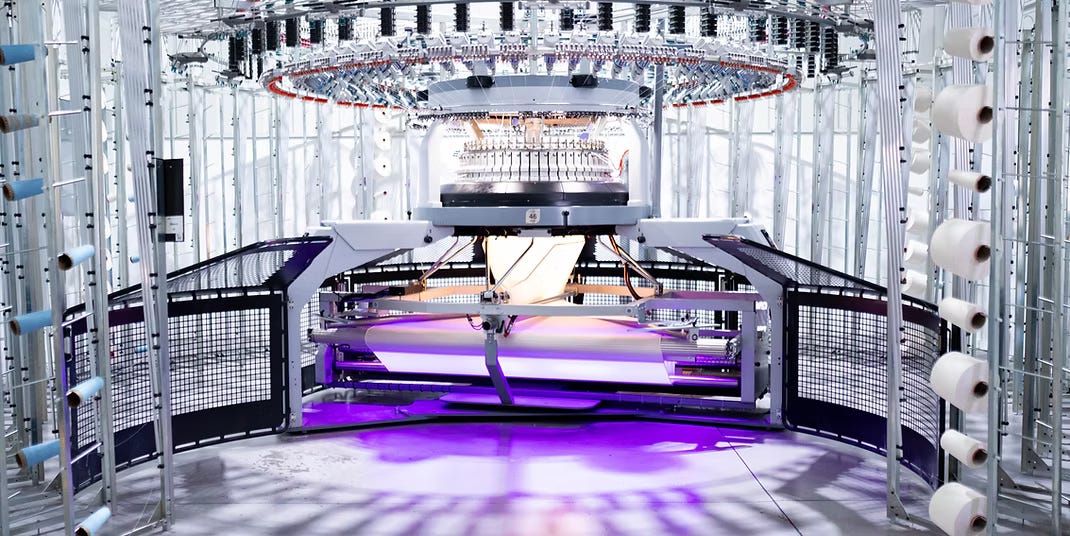

Smartex has built the AI-powered eyes textile factories need. They install cameras and computer vision systems directly inside knitting machines to detect defects the instant they appear. They’re awesome:

Real-Time Defect Detection (Smartex CORE): Cameras monitor fabric quality within 10 centimeters of where it's being made. The AI analyzes images in real time and can spot defects that are even invisible to the human eye. When a problem is found, production is immediately paused so technicians can fix the issue before more material is wasted.

100% Automated Inspection: Smartex inspects 100% of the fabric in real time. No breaks, no fatigue, no human error. This brings defect-related waste down to nearly zero.

Factory Digitalization (Smartex FACT): Beyond defect detection, Smartex digitizes entire factory operations. Managers can monitor and control production from anywhere, replacing paper-based workflows with real-time dashboards, reports, and alerts.

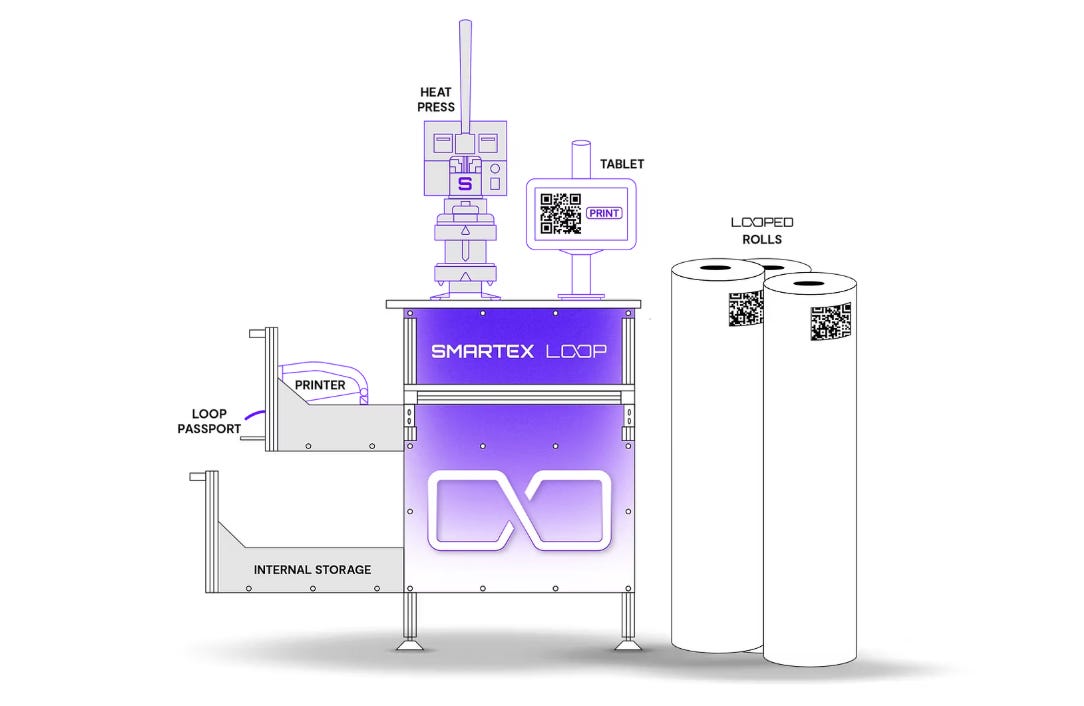

Full Traceability (Smartex LOOP): Every fabric roll gets a digital record capturing how it was produced, quality data, and full supply chain traceability. This is huge for brands that need transparency in their supply chains.

Proven ROI: 100% of Smartex's pilot projects with manufacturers have converted into sales. Everyone who sees the system in action wants it. Factory owners in Bangladesh and Vietnam demand proof of ROI within a year, and Smartex delivers.

Market 🌐

The global AI in textile market was valued at $2.6 billion in 2024 and is projected to reach $43.8 billion by 2034 (that’s a crazy CAGR of 32.4%).

This makes total sense. With labor costs in Asia's textile hubs rising 12-15% annually, tightening environmental regulations, and fashion brands demanding zero-defect supply chains, the business case for automated inspection has become irresistible.

Other Key Players

Uster Technologies 🇨🇭: A well-established Swiss company providing quality monitoring instruments for the entire textile value chain. Traditional testing equipment rather than real-time AI-powered defect prevention.

Jidoka 🇮🇳: Indian startup using computer vision for fabric defect detection, primarily focused on post-production inspection rather than real-time, in-machine monitoring.

Smartex stands out because it detects fabric defects directly inside the production machine, allowing issues to be prevented immediately rather than discovered after manufacturing.

Founding Story 🦄

Smartex was founded in 2018 by Gilberto Loureiro, Antonio Rocha, and Paulo Ribeiro in Portugal. They launched the company with just €5,000.

Loureiro grew up around textile factories. His family worked in the industry, and he was operating knitting machines and inspecting fabric as a teenager. He had a complicated relationship with it: he loved the problem-solving, but hated the inefficiency and the manual, error-prone inspection work. After earning a master's in physics, he saw a clear opportunity: the largest industry still untouched by technology was also one of the world's biggest polluters.

He brought in Rocha as CTO and Ribeiro as VP of Engineering, and the three set out to fix it. They showed their first prototype to Calvin Klein and raised their first funding round in 2019.

They have since raised over $30 million in total from the some of the world’s top VCs and fashion brands. Their tech is working in factories all around the world and they are recognized by the European Commission as foundational to Industry 4.0 in textiles.

Top Impact Stats 📈

Already prevented 792,000 kg of fabric from going to waste, saved 94 million liters of water, 17 million kWh of energy, and avoided 4.6 million kg of CO₂ emissions.

Their tech enables production of 0.37% more garments per kilogram of finished fabric. Sounds small, but applied to an industry giant like Inditex (678,596 tonnes of raw materials in 2024), translates into enormous savings.

100% of pilot projects have converted into paying customers. In the 23-year history of Lightspeed Venture Partners, they said they rarely see companies like this.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: Automation and AI systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday:)