#90 Artyc

Decarbonizing cold chains

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we’ll distill a company that’s revolutionizing sustainable cold chain logistics with battery-powered coolers: Artyc 🇺🇸

Do you use Google Drive and love color coding to stay organized? 🎨

If so, check out this extension I built that lets you customize any folder with UNLIMITED colors. 👀

Your Drive will feel truly yours.

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Artyc Tackle❓

They address the environmental impact of traditional cold chain logistics, responsible for transporting temperature-sensitive goods like medical supplies, biologics, and specialty foods.

1. Massive Refrigerant Emissions: Traditional refrigeration relies on hydrofluorocarbons (HFCs) as coolants, super-pollutants with global warming potential hundreds to thousands of times greater than CO2.These gases leak throughout a system's lifetime, with rates as high as 25% annually in food retail.

2. Food Spoilage: Cold chain spoilage accounts for $30B in lost goods each year, medicines and vaccines that never reach a patient. 14% of food is lost between harvest and retail due largely to poor temperature control. Wasted money, resources and unnecessary extra emissions.

3. Zero Visibility: Traditional cold chain provides shippers with little data on temperature or location of goods during transport. Without real-time monitoring, companies cannot detect temperature issues until it’s too late, leading to unnecessary spoilage and making it impossible to identify and fix system failures.

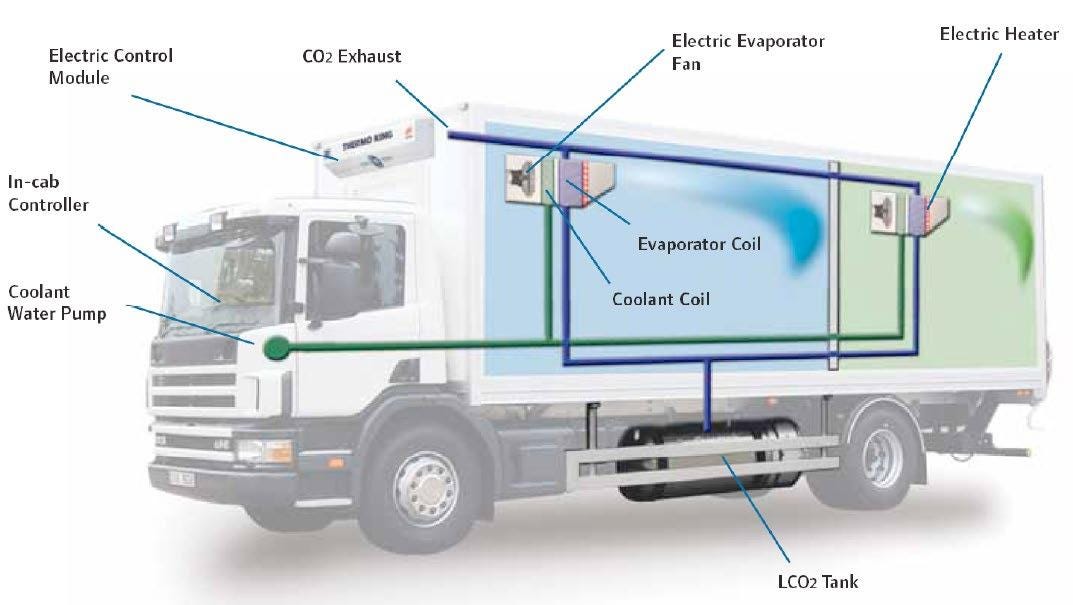

4. Energy-Intensive Operations: In developed economies, the cold chain can account for up to 3.5% of CO₂e emissions through its massive energy consumption. Traditional systems rely on continuous power from the grid or diesel generators to run compressors and maintain temperatures.

Product / Service 📦

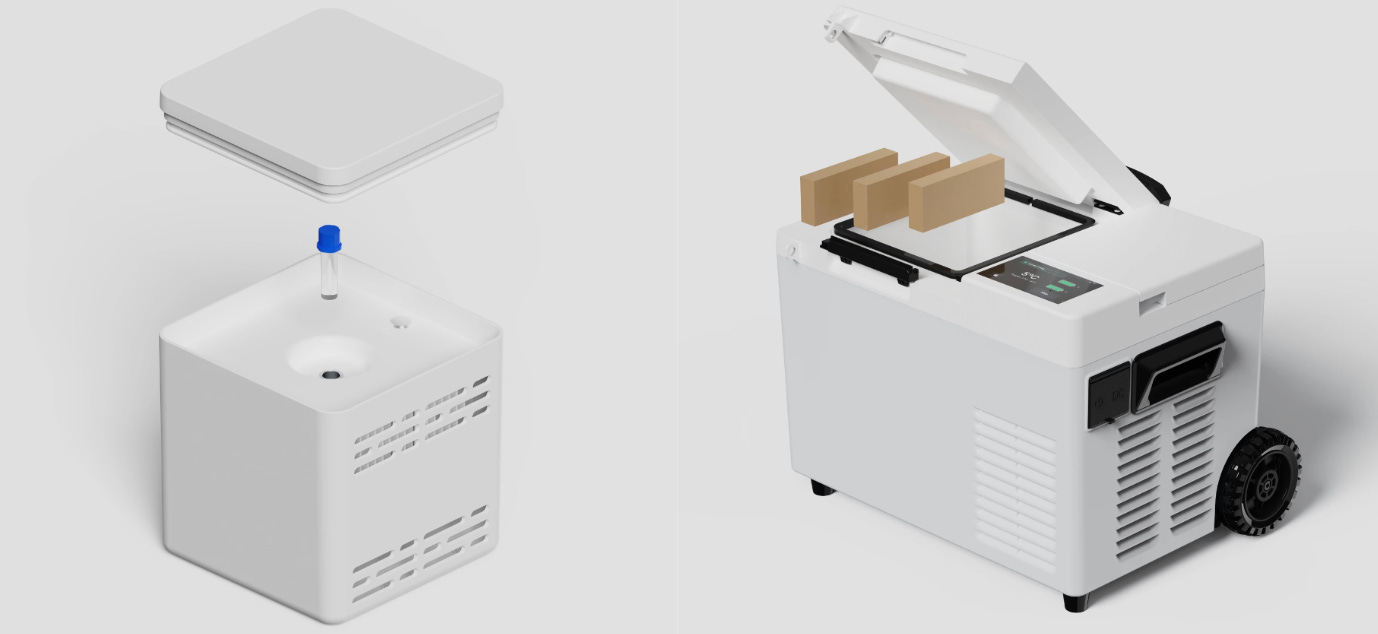

Artyc's smart and reusable battery-powered coolers eliminate refrigerants entirely while making cold chain transportation more reliable and trackable. They rock:

Refrigerant-Free Cooling: No HFCs at all. Artyc uses battery-powered compressor technology that dynamically adjusts to ambient conditions. This eliminates super-pollutant leaks while maintaining precise temperature control for days rather than hours.

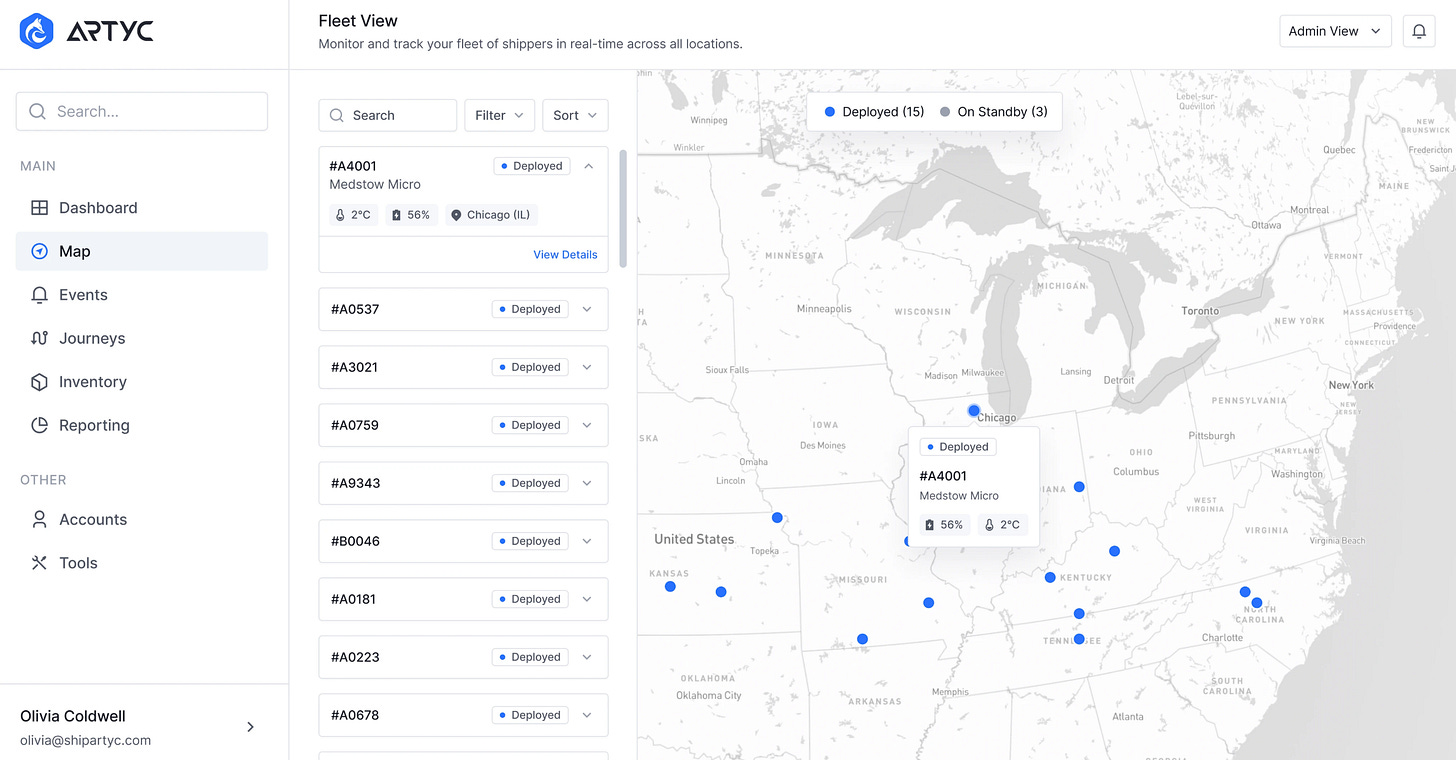

Real-Time Monitoring: Onboard sensors track GPS, temperature, battery, lid openings, and shock events. Artyc's portal provides complete info showing where samples are, how cold they are, and who accessed them without opening the lid.

Reusable Design: Replaces single-use styrofoam, gel packs, and dry ice with rechargeable units. Medstow Micro achieves carbon breakeven after just 2 shipments and reduces CO2 emissions by 60% after 10 shipments compared to traditional passive coolers.

Precision Control: Maintains 2°C to 8°C for over 56 hours, even when ambient temperatures reach 37°C or drop to -5°C. Artyc maintains cold chain compliance for 72+ hours while passive solutions fail after 35 hours.

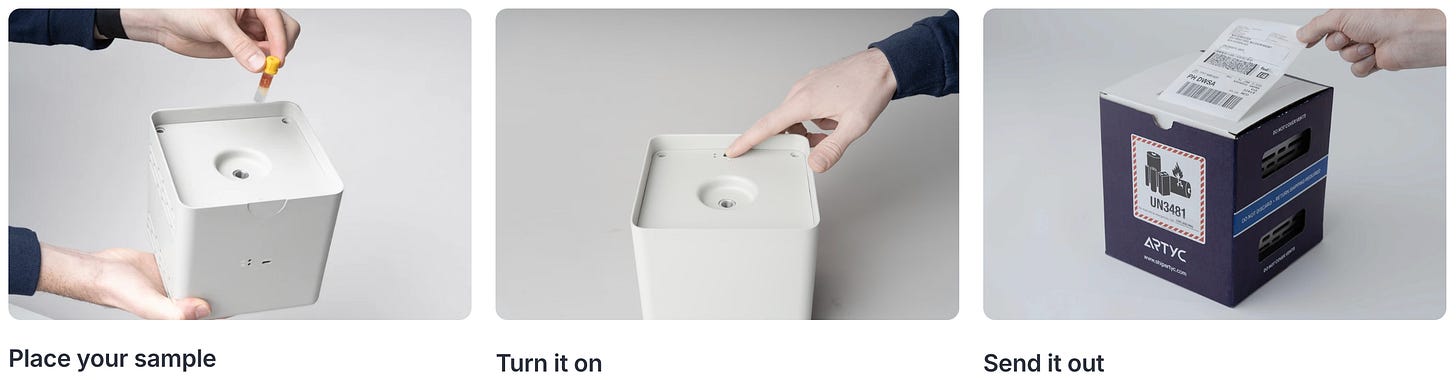

Scalable Product Line: Medstow Micro for medical microsampling, Medstow 5L for hospital transport and clinical trials, with larger formats planned for temperature-sensitive foods like herbs, chocolate, and wine.

Cost Effective: Lowers cost per shipment after a few uses by replacing packaging, tracking, and operational costs with one reusable system. Eliminates dry ice procurement and hazardous material disposal expenses. Drastically improves reliability and reduces spoilage losses.

Market 🌐

The global cold chain logistics market was valued at $325 billion in 2024 and is projected to reach $860 billion by 2032.

E-commerce keeps expanding and demand for temperature-sensitive pharmaceuticals, biologics, and perishable foods keeps rising. On top that, HFCs are the fastest-growing climate pollutant worldwide, and refrigerant management ranks as one of the top solutions to reverse climate change.

Plus…stricter regulations requiring energy-neutral operations are strongly driving demand for sustainable cold chain solutions.

Other Key Players

Swiss Airtainer 🇨🇭: Produces lightweight temperature-controlled air cargo containers with solar panels and IoT monitoring for pharmaceutical air freight. 40% lighter than competitors, reducing CO2 emissions by 48% per flight.

Tan90 🇮🇳: Uses proprietary Phase Change Materials (PCM) for passive temperature control in insulated boxes. Maintains ±1°C stability for 96+ hours without active power, targeting food, pharma, and last-mile delivery in India and Southeast Asia.

Most companies focus on monitoring or passive cooling or not as efficient active cooling. Artyc brings it all together: Active, super efficient and advanced monitoring.

Founding Story 🦄

Artyc was founded in 2021 by Hannah Sieber and Mark Langer, who met at Stanford.

Sieber previously co-founded EcoFlow, a portable power station company (now valued at $1B+) and was recognized on Forbes 30 Under 30. While pursuing her MBA at Stanford, she became obsessed with the cold chain problem after learning that refrigerants and inefficient logistics were responsible for 4% of global emissions.

Langer brought technical expertise from building electric autonomous cargo drones at Amelia and software engineering at NASA. The two realized batteries could revolutionize cold chain transportation the same way they transformed energy access.

They spent months interviewing cold chain operators and their breakthrough came when they realized they could eliminate the need for refrigerated infrastructure entirely with battery-powered active cooling.

They launched Medstow Micro for medical samples in 2023 and raised $14 million. In 2024, Artyc was named a World Economic Forum Technology Pioneer and launched Medstow 5L for hospital transport and clinical trials. They continue expanding their product portfolio.

Top Impact Stats 📈

1. 7x more energy efficient than refrigerated shipping containers.

2. Carbon breakeven after just 2 shipments with Medstow Micro.

3. 100% reusable containers and 0 refrigerants.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: Automation and AI systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday:)