#87 Traceless

Plastic-free materials

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we’ll distill a company that’s turning plant residues into a super biomaterial to substitute plastic: Traceless 🇩🇪

This issue is sponsored by B Lab Spain:

With the launch of the new B Corp standards earlier this year, they created a 100% on-demand training (+30h of content) so you can learn how to apply them in your company’s daily work and achieve an impact business model.

As a reader of this newsletter, you get an exclusive 25% discount using the code: THECLIMATECOO25 (offer expires Dec. 19th). Join 300+ professionals who have already enrolled.

Want to sponsor Climate Tech Distillery? Here’s all the info.

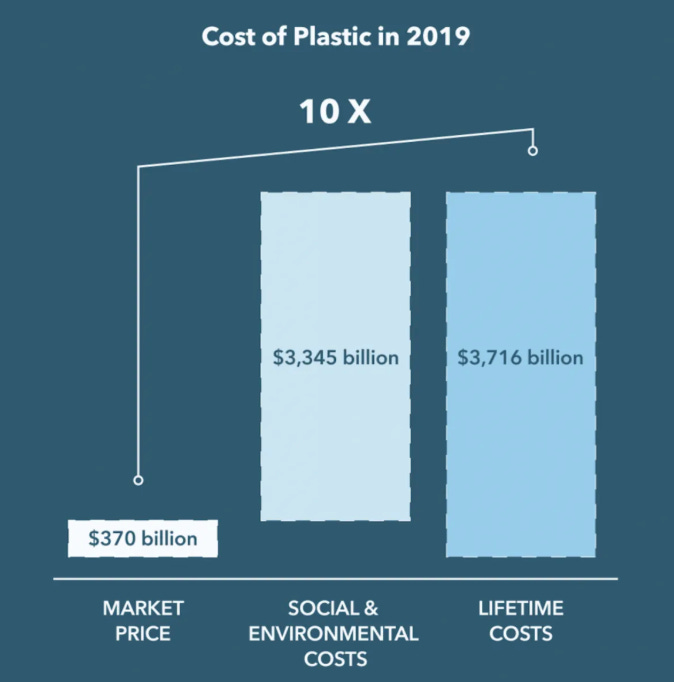

What Problem Does Traceless Tackle❓

Plastic pollution is one of the world’s most urgent crises, and the alternatives currently available often fall short. How big of an issue is it?

1. Huge Amounts: Since the 1950s, 8.3 billion metric tons of plastic have been produced, with 79% still in landfills or the natural environment. Conventional plastic degrades into harmful microplastics over time, which are way more difficult to eliminate.

2. Emissions Intensity: Producing plastic is a very energy intensive process, and mostly uses fossil energy. Plus, plastic itself is made of fossil energy resources. Plastic production is by far the largest industrial oil, gas, and electricity user in the EU.

3. Health: Conventional plastics and some alternatives rely on harmful substances, like PFAs (also know as “forever chemicals“), that pose a risk to human health and the environment during their lifecycle.

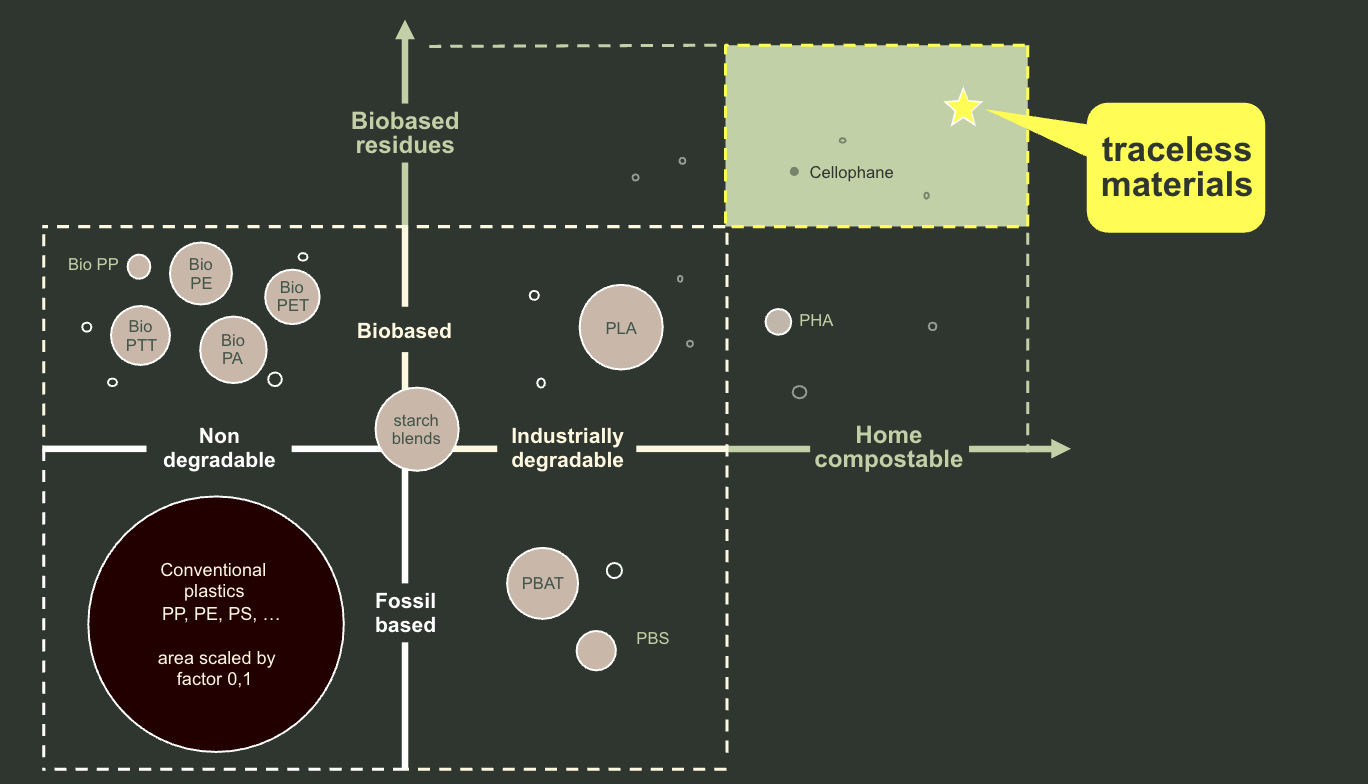

4. Alternatives’ Drawbacks: Either by still being petroleum-based, creating a ‘food vs. material’ conflict, or not fully degrading in natural environments. Many bioplastics require specific industrial composting facilities to break down and can even contaminate conventional plastic recycling streams.

Product / Service 📦

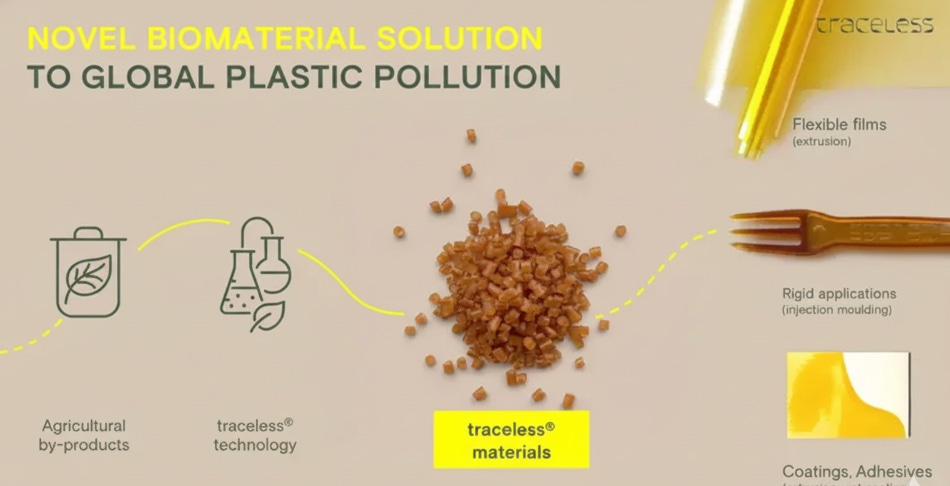

They developed a patented material called traceless® made with agricultural plant leftovers. Key benefits?

The Material: It’s a natural-based granulate produced using agricultural plant residues (like grain processing leftovers). No more ‘food vs. material’ conflict.

Just Like Plastic: The granulate can be processed using existing, standard technologies (like injection molding, film extrusion, and coating) without requiring companies to invest in new machinery.

Versatility: The materials work for many applications: consumer goods packaging, gastronomy and food service, retail and e-commerce, etc.. They focus on plastics that are hard to recycle or easily pollute the environment, such as single-use items, paper coatings or adhesives.

Zero Trace: It’s certified plastic-free (very few of those) and breaks down under natural composting conditions into water, humus and CO₂ in 2 to 9 weeks. It leaves behind no microplastics.

Environmental Impact: 0 harmful chemicals in both product and process, it can be composted and turned into nutrients for new plants to grow, requires way less land and water, efficiently produced with renewable energy, and has a very small carbon footprint. Full LCA (life cycle analysis).

Market 🌐

The biodegradable plastics market is still small but booming thanks to legislation:

The EU Plastic Strategy wants all plastic packaging to be recyclable or reusable by 2030. Since 2021 the EU plastic tax makes member states pay 0.80 €/kg of non‑recycled plastic packaging waste.

Other Key Players

Notpla 🇬🇧: Biodegradable packaging solutions made out of brown seaweed to substitute single use plastics.

Sulapac 🇫🇮: Biodegradable materials made from plant‑based polymers and side‑stream wood or natural fillers to replace plastic in food and cosmetics.

Ecovative 🇺🇸: Specializes in mycelium-based packaging, using mushroom roots to create biodegradable materials as alternatives to traditional plastic foams.

Founding Story 🦄

Traceless was co-founded in 2020 by Dr. Anne Lamp (CEO) and Johanna Baare (COO), who met at the “Act on Plastic Challenge” incubator.

Lamp, driven by her passion for sustainability and prior experience founding the NGO Cradle to Cradle, invented the core technology for Traceless during her PhD at Hamburg University of Technology. Her commitment to finding a scalable, real-world solution was profoundly influenced by a sailing trip where she personally encountered a large “plastic carpet” polluting the ocean.

Johanna brought the entrepreneurial, business strategy and scaling expertise to complement the technical invention.

They’ve raised €42 million to date, they’re currently building their first industrial production plant, and they have partnerships with huge players like Mondi (for paper coatings) and the Otto Group (for e-commerce packaging).

Top Impact Stats 📈

Up to 95% lower CO₂ emissions over production and disposal compared with conventional virgin plastics.

Each ton of Traceless material produced saves 2.8 football fields of land and 20k liters of water compared with conventional virgin plastics.

Traceless materials require 83% less fossil energy demand during production than conventional virgin plastics.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: Automation and AI systems for climate/impact companies so they can free up time, scale their revenues and cut their costs.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you on Jan 10th, enjoy the holidays :)

Fantastic breakdown of Traceless! What really makes this standout is their decision to use existing manufacturing tech instead of requring new machinery. I worked with a sustainable packaging startup before and teh capital barrier was massive, companies just wouldnt invest. This compatability angle solves the chicken-egg problem that kills most biomaterial innovations at scale.