#80 Redwood Materials

The infinite battery loop

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we’ll distill a company that extracts key metals from end-of-life batteries to make new critical battery components and also builds energy storage systems using second-life EV batteries: Redwood Materials 🇺🇸

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Redwood Materials Tackle?

They deal with several issues related to the massive battery production and waste crisis.

1. Crazy Demand, Little Recycling: As EVs and energy storage rapidly scale, demand for batteries keeps skyrocketing. Discarded batteries contain valuable materials, yet less than 5% are currently recycled in the US. The rest end up in landfills or are shipped overseas for processing.

2. Critical Material Scarcity: Mining virgin lithium, cobalt, and nickel is difficult, expensive, environmentally destructive and involves questionable labor practices. Plus, mining operations can’t keep up with the demand.

3. End-of-Life Battery Crisis: EV batteries last 8-15 years, meaning millions of first-generation EVs will soon reach end-of-life. Without recycling infrastructure, tons of toxic battery waste will accumulate in landfills, leaching dangerous materials into soil and water.

4. Supply Chain Vulnerability: 80% of battery production happens in Asia, creating geopolitical risks for Western automakers. The lack of domestic material processing makes the battery supply chain vulnerable to global disruptions.

5. Economic Waste: Each discarded EV battery contains $1,000-2,000 worth of recoverable materials. Without recycling, this value is lost, making EVs more expensive and slowing the clean energy transition.

Product / Service 📦

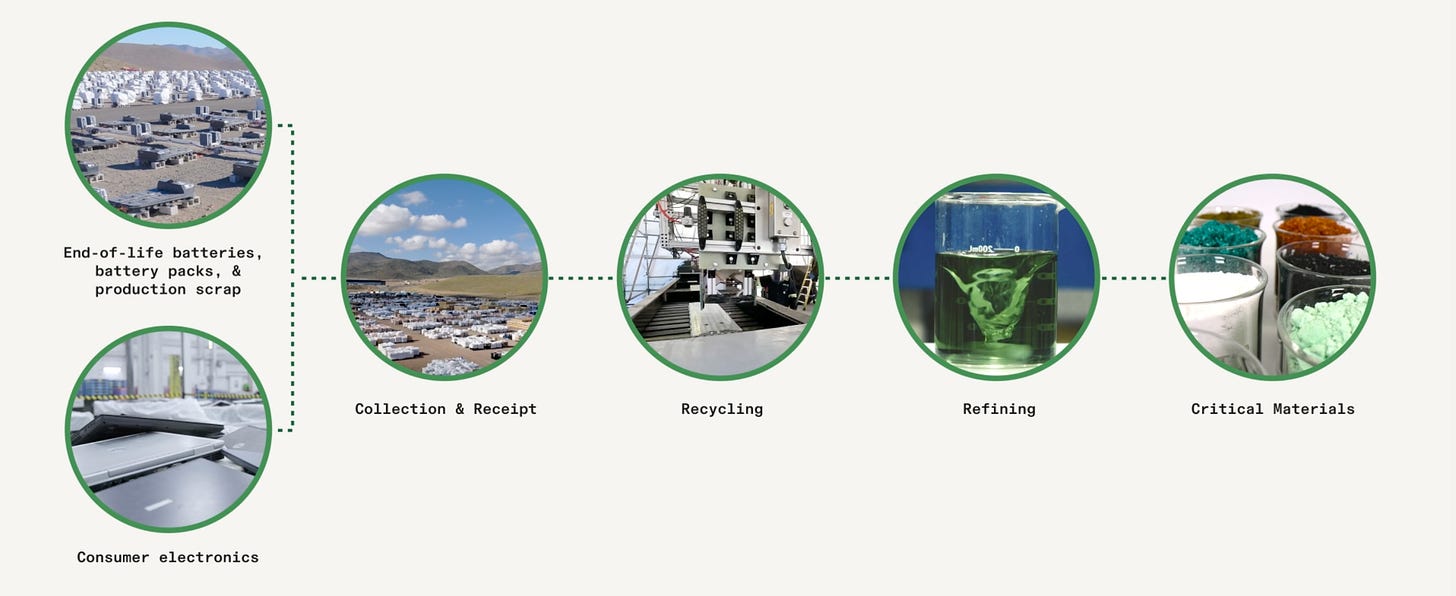

Redwood Materials has created a circular supply chain for lithium-ion batteries. They recover critical materials from end-of-life batteries and manufacturing scrap, then refine them into battery components. Pretty awesome:

Advanced Recycling Process: Their processes recover +95% of critical materials like lithium, cobalt, nickel, and copper from batteries. They extract all valuable components while maintaining material purity comparable to virgin materials.

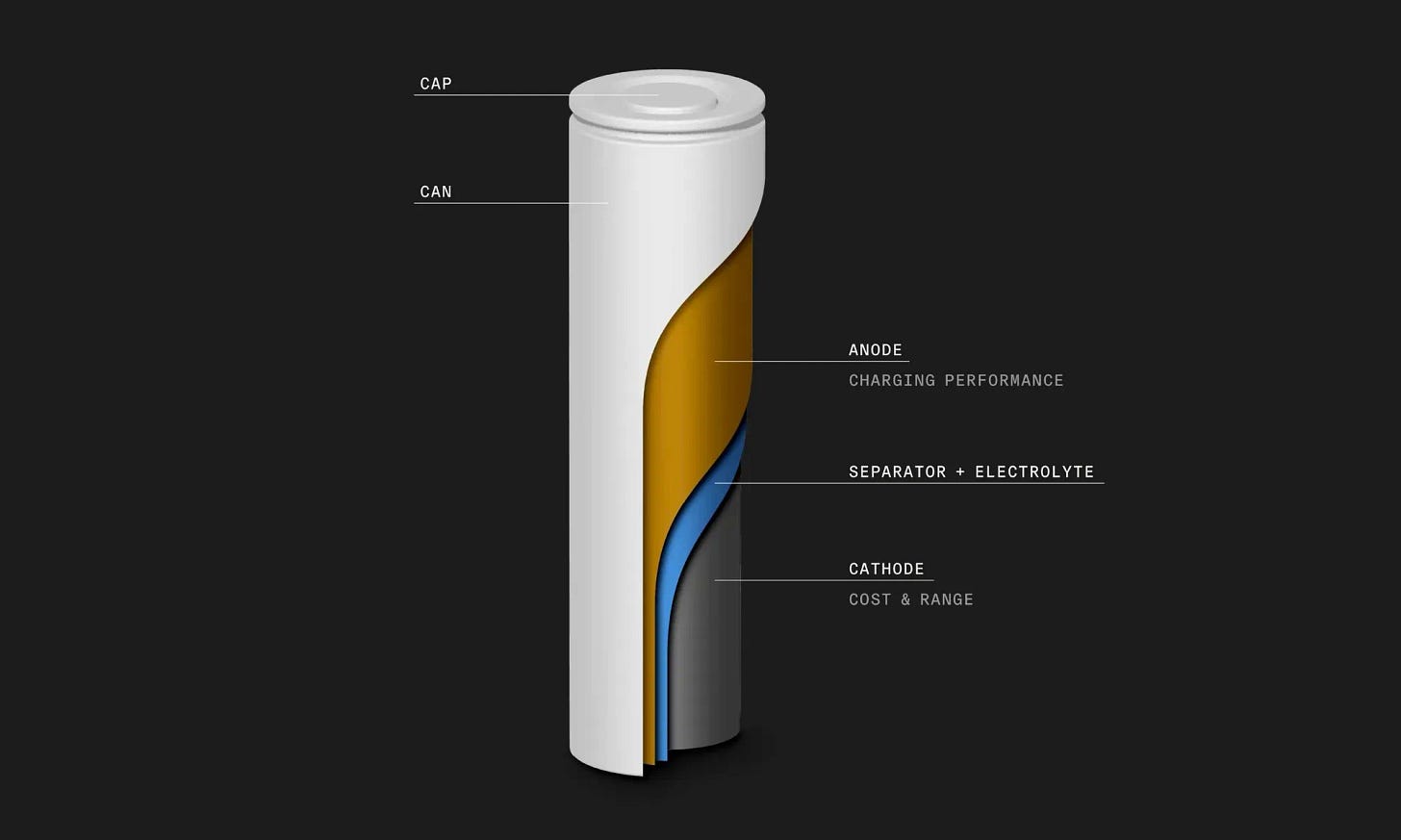

Battery Component Manufacturing: They refine recovered materials into anode copper foil and cathode active materials (the most expensive battery components). This creates a closed-loop system where old batteries become new ones.

Collection Network: Redwood partners with automakers (Ford, Toyota, Volkswagen), battery manufacturers (Panasonic, FREYR), and retailers to collect end-of-life batteries and manufacturing scrap.

Energy Storage Solutions: Given the huge electricity demand from data centers, Redwood now also designs, integrates, and deploys large-scale battery storage systems using new and repurposed batteries at the lowest cost.

Cost and Environmental Impact: Recycled materials cost 20-30% less than newly mined ones while producing significantly lower carbon emissions (cutting battery production emissions by up to 80%).

Market 🌐

These 3 mind-blowing stats help confirm how necessary battery recycling is…

By 2040, the value of recyclable materials from end-of-life batteries could reach $57 billion annually.

The global EV battery market is expected to grow from 700 GWh in 2024 to over 4,500 GWh by 2030.

By 2030, lithium demand is projected to increase by 500%, cobalt by 460%, and nickel by 340%.

Other Key Players

Ascend Elements 🇺🇸: Produces advanced cathode materials from spent lithium-ion batteries using its patented hydro-to-cathode recycling process.

Tozero 🇩🇪: Focuses on recovering lithium, nickel, cobalt, and manganese from end-of-life batteries.

Founding Story 🦄

Redwood Materials was founded in 2017 by JB Straubel, former Tesla co-founder and CTO, and Andrew Stevenson, then Tesla’s head of special projects. After spending 15 years building Tesla into a giant, Straubel left to tackle what he saw as the next critical challenge: the battery supply chain.

During his time at Tesla, Straubel witnessed the massive waste from battery manufacturing and the vulnerabilities of relying on overseas suppliers. “We realized we were going to have a huge wave of end-of-life batteries coming,” he said, “and nobody was prepared to handle them.”

They started Redwood in Nevada, near Tesla’s Gigafactory to access manufacturing scrap. The company proved their technology could recover materials at high purity and low cost, securing partnerships with Panasonic, Ford, Toyota, and Volkswagen.

They’ve since raised over $2 billion from investors including Amazon and Goldman Sachs. Their Nevada facility produces materials for 1 million EVs per year, and they’re building one in South Carolina that will scale production to 5 million EVs annually by 2030.

Top Impact Stats 📈

They use 80% less water and 70% less energy than traditional mining operations for obtaining battery materials.

They process over 20 GWh of batteries annually (equivalent to 250K EVs) representing about 90% of all lithium-ion batteries and battery materials recycled in North America.

80% lower carbon emissions compared to mining and refining virgin materials. At full capacity, will avoid 3.5 million tons of CO2 emissions annually.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: I build low-code automation systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday:)