#74 Circ

Turning fashion waste into new clothes

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we’ll distill a company that’s making fashion circular at scale by endlessly transforming complex textile waste into new textiles: Circ 🇺🇸

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Circ Tackle❓

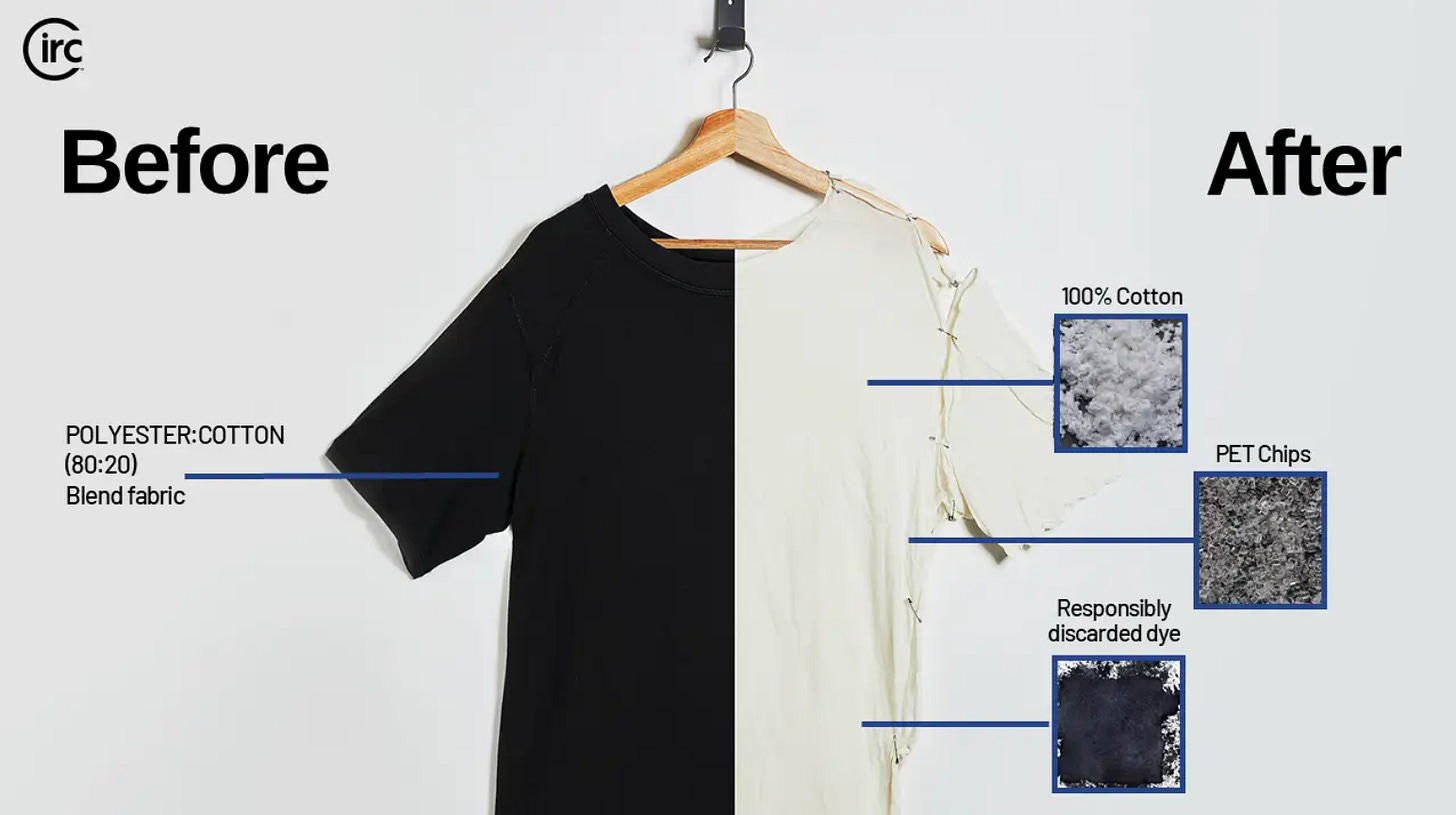

They specifically deal with the massive volume of discarded polyester-cotton (polycotton) blends that are currently filling up landfills and are considered “unrecyclable” with current tech.

1. Massive Textile Waste Crisis: The global fashion industry produces around 92 million tonnes of textile waste annually, with less than 15% being recycled. The rest are incinerated or sent to landfills. This leads to approximately 120M tons CO2e/year.

2. Impossible Blend Recycling: Polyester-cotton blends, the most common textile produced, are a nightmare to recycle. Any process that preserves the polyester degrades the cotton fibers, and vice versa. Most textile recyclers today can only recycle and recover one material.

3. Ultra-Long Decomposition Times: Textiles can take up to 200+ years to decompose in landfills. This creates permanent environmental burden, as synthetic fibers persist in the environment while releasing microplastics and chemical pollutants over centuries.

4. Production Waste Scale: Due to the number of cut outs for the clothing, a large number of materials get wasted as they cannot be used any further. It is estimated that 15% of fabric used in garment manufacturing is wasted. Even before clothes reach consumers, the production process itself generates enormous waste streams.

Product / Service 📦

Circ’s textile-to-textile recycling tech changes this. They make the unusable, recyclable. Here’s why they’re so awesome:

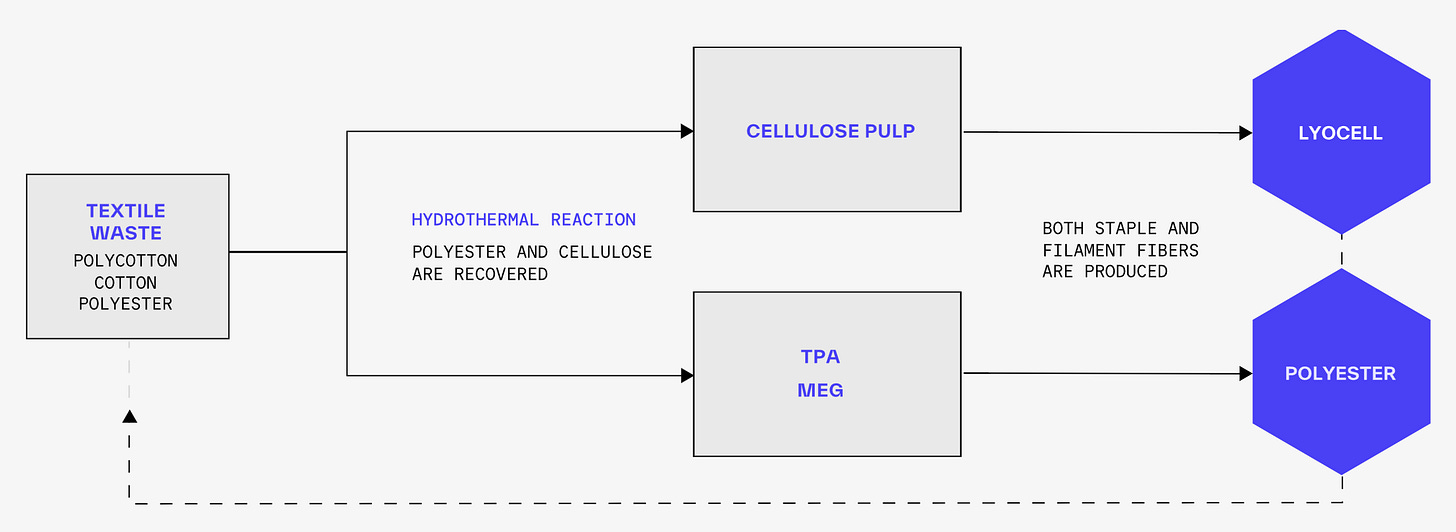

Revolutionary Separation: Their patented hydrothermal process turns polyester fibers into a liquid polymer while preserving the cotton fibers completely intact. The process only involves water, heat, pressure, and very few non-harmful chemicals. Treatment occurs at 220-230°C for just 10 minutes while maintaining fabric structure.

Material Recovery: Their technology separates and recovers both polyester and cotton (materials that make up 77% of the global textile market) and the process yields as-good-as-virgin materials. They achieve 97% recovery rate for polyester and 90% for cotton fibers in just 2 hours.

End-to-End Process: They collect textile waste from various sources, sort and mechanically resize it for hydrothermal processing, using AI to categorize textiles by material type and color before breaking them down into reusable fibers.

Scalability: They’re opening the world's first commercial plant for polycotton recycling. The massive $500 million recycling plant is being built in France, and will have the capacity to process 70k metric tons per year (equivalent to 1,750 fully loaded 18-wheeler trucks).

Sustainability Impact: Compared to virgin fibers, Circ’s process uses 80% less water, lowers emissions by 60%, uses 50% less energy, involves significantly less chemicals and drastically lowers land use (no cultivating cotton fields or producing new synthetic polymers).

Cost: Circ’s recycled fibers currently sell for prices very close to virgin fibers but are projected to become slightly cheaper as scale and adoption grow.

Market 🌐

The global textile recycling market was valued at $6 billion in 2024 and is estimated to grow at a CAGR of over 4.9% through 2034. Regulatory and customers’ pressure for circular fashion and brands' commitments to reduce textile waste are behind this growth.

Other Key Players

Infinited Fiber 🇫🇮: Transforms textile, cardboard, and agricultural waste into high-quality new natural fibers.

Circulose 🇸🇪: They turn cotton-rich textile waste into a pulp used to produce new fibers. They can only recycle white textiles.

Worn Again Technologies 🇬🇧: Focuses on chemical recycling to separate polyester and cellulose from mixed textile waste for reuse in new products.

Founding Story 🦄

Circ (originally Tyton BioSciences) was co-founded by Peter Majeranowski, Luke Henning and Conor Hartman. The company began in 2011 focused on converting tobacco plants into biofuels, inspired by Majeranowski’s desire to address energy geopolitics after his Navy service and investment career.

When investor interest in biofuels waned around 2016, the founders sought new applications for their technology and, after a successful experiment recycling a T-shirt, pivoted to textile recycling in 2018.

Circ rebranded from Tyton Biosciences in 2020 and since then they’ve achieved huge milestones. Over $90 million raised from VCs and fashion industry giants. Partnerships with Patagonia, Zara, and others. Becoming a B Corp and being one of Fast Company’s most innovative companies 2024. And of course, building the massive $500 million plant to scale their tech!

Top Impact Stats 📈

1. First and only technology to fully separate and recycle polycotton blends at scale.

2. Their plant will avoid 300K tonnes of CO2 emissions and billions of liters of water each year compared to producing virgin polyester and cotton fibers.

3. Less than 1% of clothing waste is currently turned into new clothes.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: I build low-code automation systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday:)

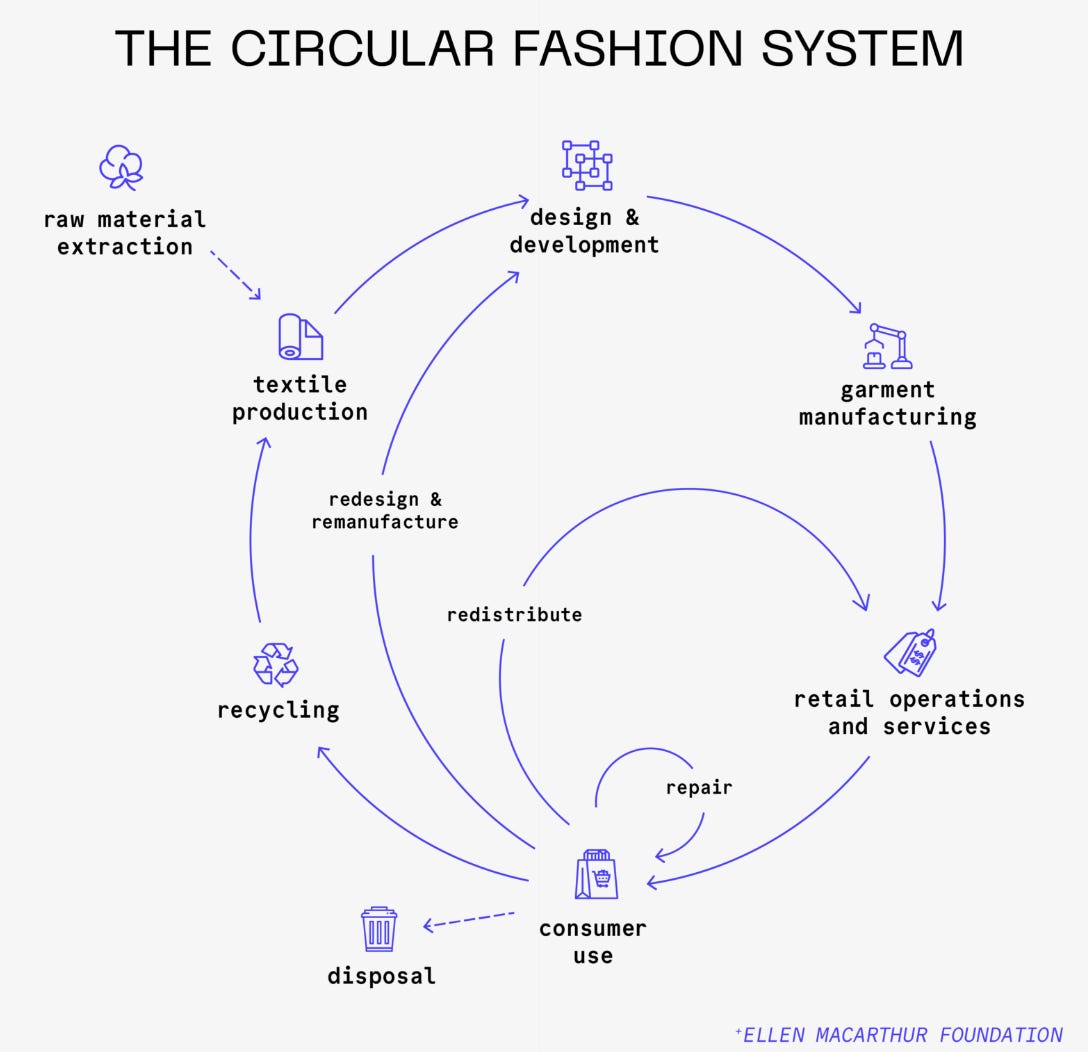

Super interesting, as always! I believe that recycling is a great way to avoid waste, but before that repairing should be more often thought of