#73 Biosphere Solar

The world's 1st fully circular solar panels

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Today we’ll distill a company that’s pioneering fully circular, supply chain traceable, and repairable solar panels designed for infinite disassembly and reuse: Biosphere Solar 🇳🇱

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Biosphere Solar Tackle❓

Solar is the cheapest energy source in many regions of the world, but it faces a huge waste crisis that threatens its clean reputation. The way traditional solar panels are currently made entails significant environmental and economic challenges:

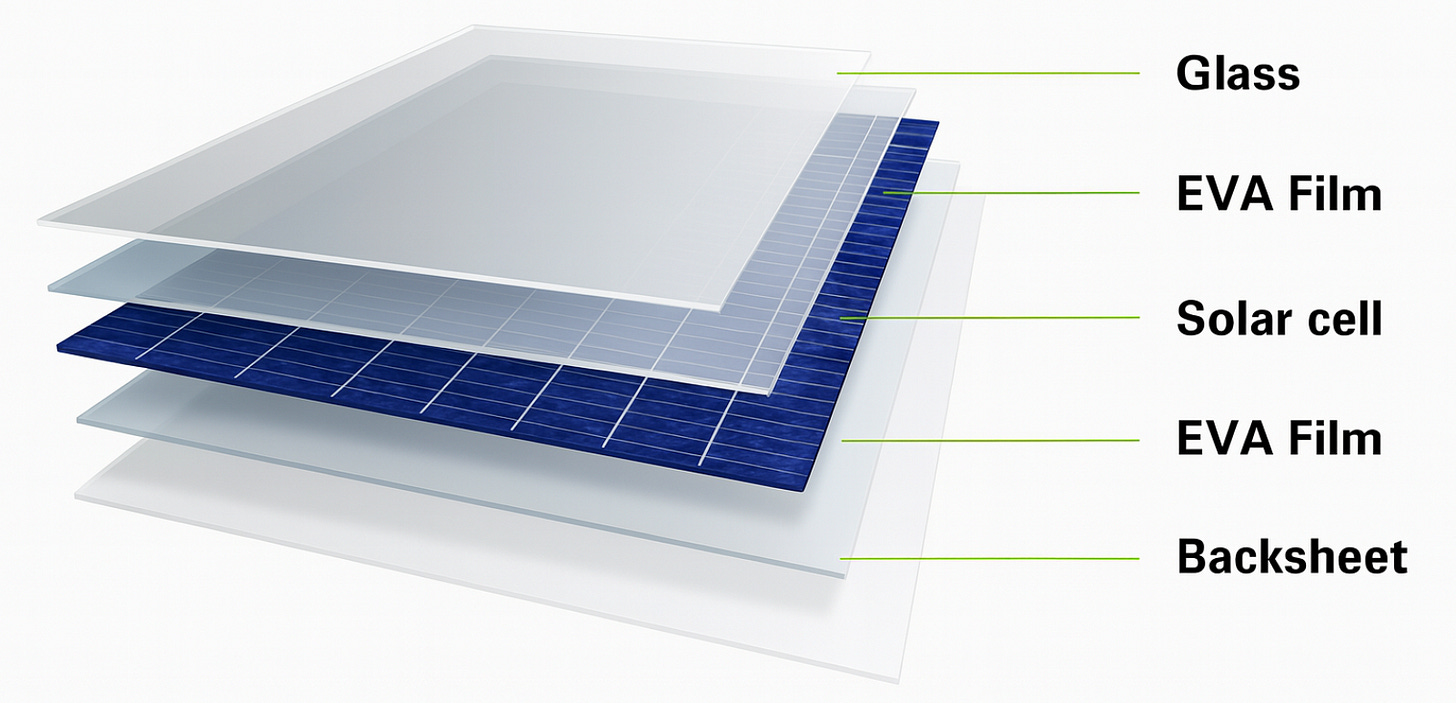

1. Recycling Crisis: Traditional solar panels are constructed using EVA (ethyl-vinyl-acetate) lamination that permanently bonds all components together, making solar panel recycling 10x more expensive than landfilling. Less than 10% of panels are currently recycled, with valuable silicon cells virtually impossible to separate intact.

2. Impossible Repairs: EVA lamination makes panels impossible to repair, meaning that when 42% of modules fail due to delamination or hotspots, they must be entirely replaced rather than fixed, creating unnecessary waste.

3. Short Lifespan: Panels typically last 15-25 years before complete replacement, despite many components remaining functional. The inability to upgrade individual parts forces premature disposal of valuable materials.

4. Environmental Impact: Traditional panels will contribute to a projected 78 million tons of solar waste by 2050. That’s equivalent to 7700 Eiffel Towers…This contradicts solar's clean reputation.

5. Supply Chain Opacity: The industry lacks transparency regarding labor conditions and material sourcing, making it difficult to ensure ethical production practices throughout manufacturing.

Product / Service 📦

They make the most sustainable solar panels in the world. These are a few reasons showing how awesome they are:

Revolutionary Manufacturing: No EVA at all. They use mechanical assembly without adhesives. This allows glass, cells, and backsheets to be connected and disconnected multiple times without damage, creating a 50% less carbon intensive manufacturing process.

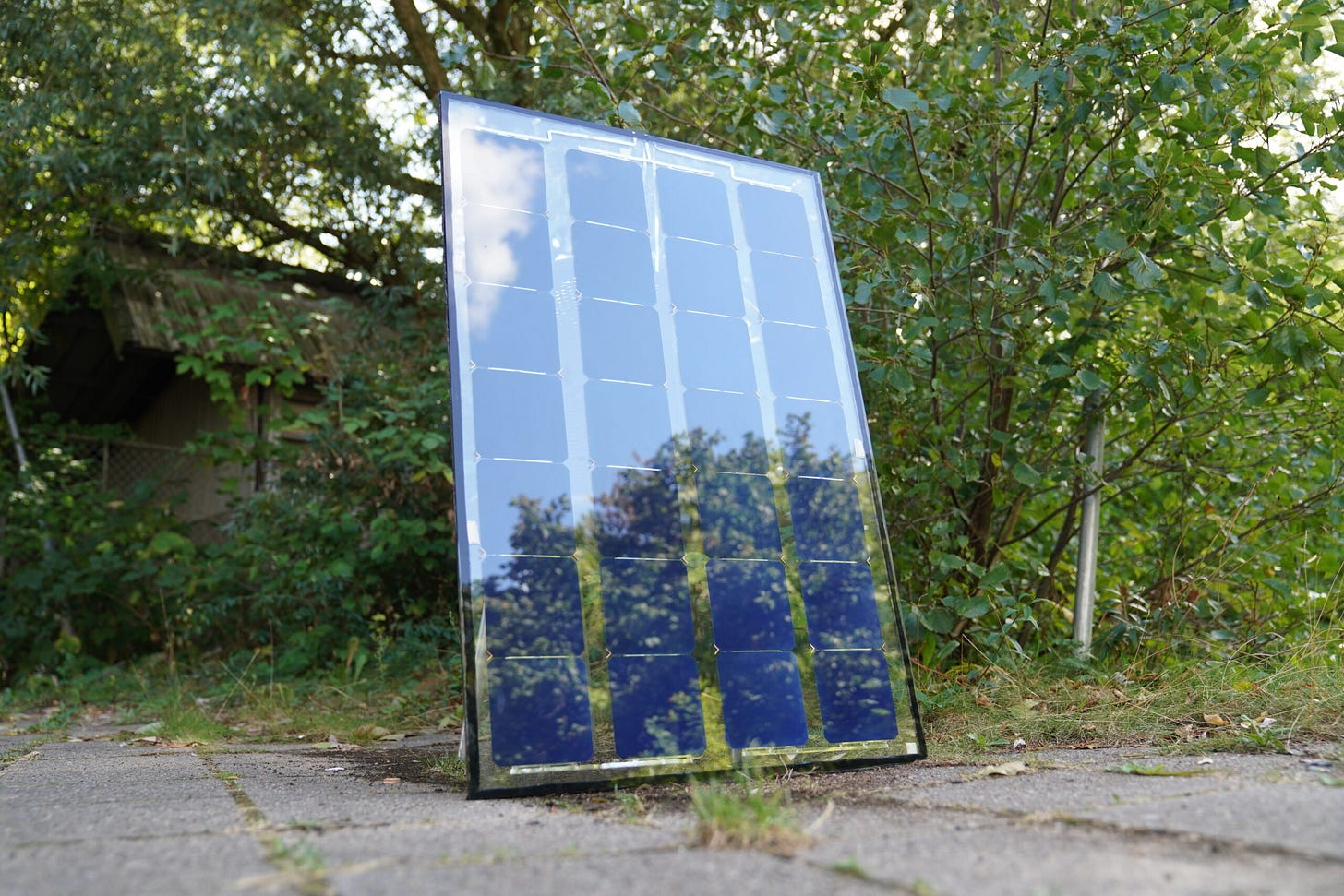

Repairability: Individual components can be replaced without scrapping the entire panel. This extends panel lifespan from 25 years to potentially 40+ years through component upgrades and repairs that local technicians can handle. Cost of ownership improves by 30-40% over the panel lifetime.

Cost and Time: Eliminates 80-90% of recycling costs by making disassembly economical instead of the typical $500-$1,000 per ton. Disassembly takes hours vs. weeks of chemical processing for traditional panels.

Circularity: Achieves 95%+ material recovery rates through easy disassembly vs 10% for traditional panels. Components maintain their value and function, preserving critical materials like silicon and silver for future uses.

Supply Chain Transparency: Each panel comes with a product passport so you know where the materials came from and how the panel was produced.

And yes, they’re just as efficient as traditional solar panels!

Market 🌐

The global solar panel recycling market was valued at $333.5 million in 2024 and is projected to reach $2.5 billion by 2034, growing at a crazy CAGR of 22.3%.

It makes sense, regulatory pressures are increasing and companies want to recover valuable materials from end-of-life panels as efficiently as possible.

Other Key Players

ROSI Solar 🇫🇷: Operates the world's first industrial recycling line able to recover high-purity materials from end-of-life solar panels. Focused on silver, silicon, and copper through chemical processing methods.

Veolia 🇫🇷: Industrial-scale solar panel recycling processes that can recover up to 95% of materials, primarily through mechanical and thermal treatments for glass and aluminum recovery.

Most companies are dealing with how to recycle traditional panels but Biosphere Solar is the only company focusing on preventing the recycling problem entirely.

Founding Story 🦄

Biosphere Solar was founded in 2020 by Siemen Brinksma, Perine Fleury, and Tim Kaasjager. The 3 of them met at the Delft University of Technology. They became increasingly frustrated with the linear nature of the solar industry and the massive waste stream it creates.

They combined their engineering, sustainability and business development skills to create the company with a clear vision: Bring circularity to the solar industry by transitioning to a reuse and repair mindset, while also addressing human rights transgressions in the globalized solar supply chain.

They have now developed several versions of their panels, they have them installed in locations all around the Netherlands and they’re setting up a global take back system to circulate all materials and components into new solar panels.

Just in case all of this wasn’t enough… they chose to open source parts of their tech so solar overall can become circular much faster. Most investors don’t love this so they rely on product sales and donations to scale.

Top Impact Stats 📈

1. End-of-life solar waste drops to nearly zero.

2. 6-8 year payback periods in EU scenarios. Even faster returns in developing regions where repair services create local jobs.

3. 10x cheaper to recycle, 35% lower total cost of ownership, and 9.5x higher material recovery rate.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: I build low-code automation systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday:)

Thanks for the great overview Javier!

Thanks for the great overview Javier!