#40 Brimstone

Transforming cement from climate problem to climate hero

Read time: 5 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Subscribe for free to receive my weekly articles in your inbox.

Today we’ll distill a company that’s decarbonizing construction with innovative, CO2-free cement: Brimstone

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Brimstone Tackle❓

Concrete is the second most used resource in the world after water and cement is one of the elements that make up concrete. The problem is traditional cement production has a massive environmental impact. In more detail:

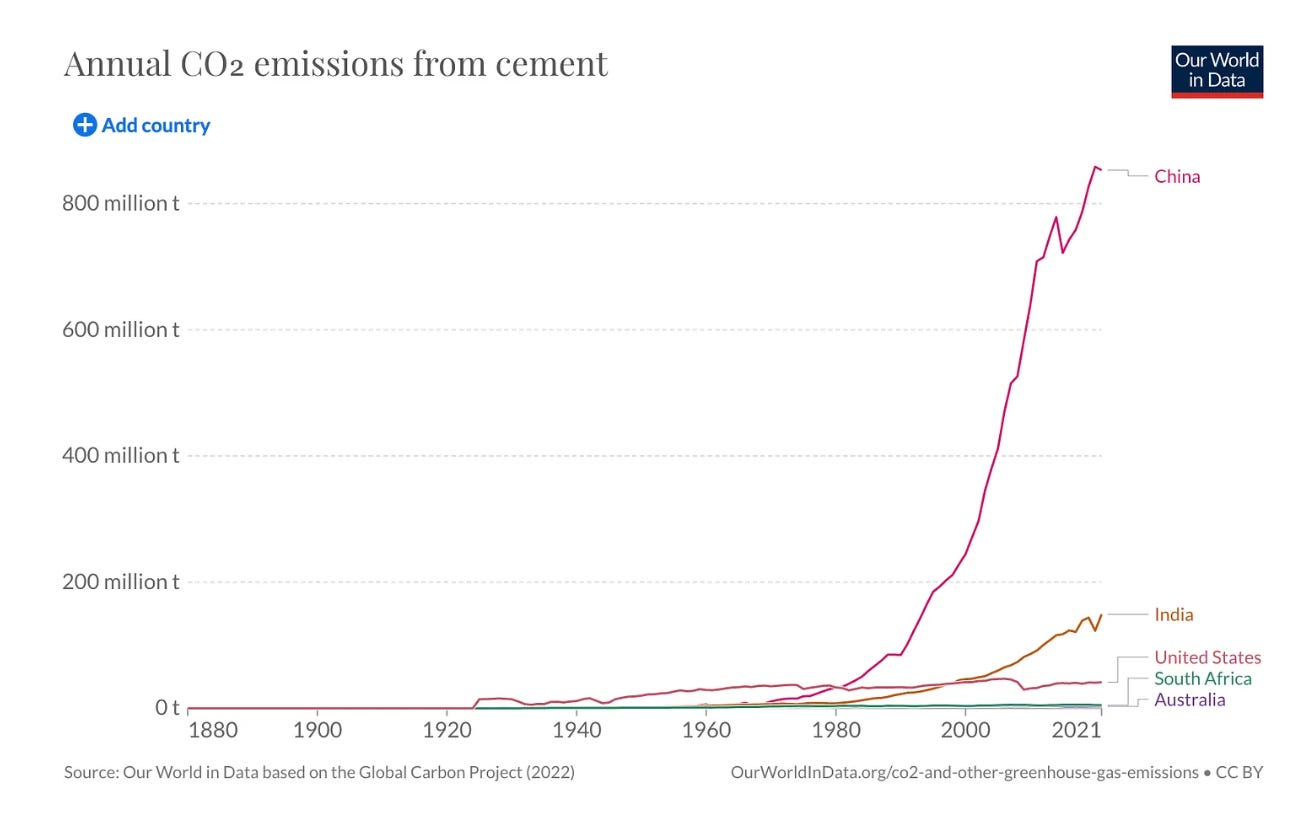

1. CO2 Emissions: Because of the way the cement is made, 1 tonne of cement = 1 tonne of CO2. We produce over 4 billion tonnes of cement a year, responsible for 8% of global CO2 emissions.

2. Resource Intensive: 60% of the emissions come from the chemical reaction of obtaining calcium oxide from limestone (CaCO3 → CaO + CO2). Another 40% comes from burning fuel to create the reaction.

3. Ecological Damage: Cement manufacturing requires large amounts of energy and resources, leading to deforestation, water pollution, and habitat destruction.

4. Growing Demand: Despite the environmental concerns, demand keeps soaring. And it makes sense, it’s only fair that developing countries want to have bigger and safer buildings.

Product / Service 📦

Brimstone created a cement that is chemically and physically identical to ordinary Portland cement (OPC), but has a much lower environmental impact because of the way it’s made.

Raw Materials: Instead of limestone, Brimstone uses carbon-free calcium silicate rocks. That switch eliminates the root problem of emissions right away. And these rocks are 100x more abundant than limestone.

Carbon Sequestration: In addition to the calcium, silicon, iron and aluminum used to make cement, their rocks contain magnesium. They use it to passively and permanently remove atmospheric CO2.

Industry-Standard Quality: Brimstone cement has the same strength, workability, and durability builders have trusted for over 150 years with traditional cement.

Cost-Competitive: They are the only manufacturer capable of making cost-competitive zero-carbon cement. When operating at industrial scale, Brimstone's cement can be produced below current market prices.

Product Efficiency: Their produces two core products used in concrete: ordinary Portland cement and supplementary cementitious materials (SCM). Today, cement and SCM are made from different processes and sourced from different locations. Their rocks contain all the minerals necessary to make both cement and SCM from one process in one location!

Basically a game-changer to support net-zero construction.

Market 🌐

The global cement market is expected to grow at a CAGR of 5.24% during 2024-2030. Especially driven by Africa and India. But even if demand were to remain constant…we produced 4.39 billion tons in 2024! That number alone is massive enough to provide a huge opportunity for decarbonization.

Demand for sustainable cement solutions is also increasing, driven by regulatory pressures and consumer preferences, making it a promising segment within the broader cement industry. The question is, how fast can we scale production to 4 billion tonnes per year?

Other Key Players

CarbonCure 🇨🇦: They inject captured CO2 into concrete during mixing, where it mineralizes into calcium carbonate, making the concrete stronger while permanently trapping the CO2.

Sublime Systems 🇺🇸: They make ultra-low carbon cement through an electrochemical process that operates at room temperature, completely eliminating the need for high-temperature kilns and fossil fuels

Founding Story 🦄

Brimstone was founded in 2019 at Caltech by Cody Finke and Hugo Leandri. They began working on solutions to some of the world’s most overlooked environmental problems and the cement industry has always been considered one of the most challenging to decarbonize.

Cody holds a Ph.D. in environmental science and engineering and has experience in electrochemistry and techno-economic modeling. Hugo is a mechanical engineer, environmental science researcher at Caltech and his dad owned a concrete and crushing company. Their combination was perfect and Cody’s Ph.D laid the groundwork for their innovative approach.

The founders knew the product would need to be chemically and physically identical to the ordinary portland cement that builders everywhere know and trust. On top of that, the process would need to be extremely low-carbon and cost-competitive at scale.

Since then they have raised over $60 million from the world’s best climate VCs and in 2024 they got this…

Top Impact Stats 📈

They will avoid 120,000 metric tons of CO2 emissions annually at their first commercial plant. That’s like 312,000 round-trip flights between New York and Miami.

Their cement is carbon negative! The process generates magnesium compounds that permanently absorb CO2 from the air, making their cement production carbon-negative across various energy scenarios.

Once Brimstone scales, their cement will be cheaper than traditional cement, with the same quality and not harmful to the environment. A no-brainer innovation with the potential to eliminate 8% of global CO2 emissions.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: I build low-code automation systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday :)