#38 Cyclic Materials

Creating a circular economy for rare earth elements

Read time: 4 minutes

Hi, I’m Javi Gascón.

This is Climate Tech Distillery, a newsletter where I talk about one specific climate tech company every week.

Subscribe for free to receive my weekly articles in your inbox.

Today we’ll distill a company that’s closing the loop on rare earth elements with circular recycling: Cyclic Materials 🇨🇦

Scale your climate company with today’s sponsor:

The Climate COO leverages AI and process optimization to build automation systems for climate companies. Sales and marketing, operations, project management, you name it.

If you want to boost growth and streamline operations, this is a great place to start. They offer both one-off projects and automations as a service subscriptions.

Want to sponsor Climate Tech Distillery? Here’s all the info.

What Problem Does Cyclic Materials Tackle❓

They deal with the problem of the unsustainable and unreliable supply of rare earth elements (REEs). REEs are those elements no one talks about yet we all need for all sorts of devices (lanthanum, cerium, praseodymium, neodymium, etc.).

The problem can be broken down into several key issues:

1. Dependence on Foreign Sources: The current supply chain for REEs is highly dependent on China, creating geopolitical and supply chain risks.

2. Environmental Impact: Traditional mining of REEs results in significant environmental damage, including the removal of large amounts of earth (up to 250 tons per carat), water pollution, and deforestation.

3. Increasing Demand: The demand for REEs is escalating, driven by the growth in technologies such as wind turbines, electric vehicles, and electronics. The global market for magnet-containing REEs is forecasted to increase 3X by 2030.

4. Waste and Resource Depletion: The lack of recycling infrastructure leads to substantial waste, with magnets and other products containing REEs often ending up in landfills rather than being recycled.

Addressing these issues is crucial for supporting the transition to an electrified and sustainable economy.

Product / Service 📦

Cyclic Materials recycles and recovers rare earth elements (REEs) from magnetic waste, such as magnets from electric motors, wind turbines, MRI machines and other electronic devices. Then they also produce materials for new magnets. Rare Earth magnets are some of the strongest in the world and they are critical for the world.

What do they achieve you ask?

Sustainable Supply Chain: Cyclic Materials creates a circular supply chain for REEs, reducing the need for new mining and the associated environmental impacts.

Reduced Waste: The recycling process minimizes landfill disposal of magnetic waste, contributing to a more environmentally responsible approach.

Local and Secure Supply: By recovering REEs domestically, it enhances the security and reliability of the supply chain, reducing dependence on foreign sources.

Support for Green Technologies: The recycled REEs are essential for the production of green technologies such as electric vehicles, wind turbines, and other electronics, supporting the global transition to a more sustainable economy.

This is one of those problems most people don’t know about, yet it’s crucial to figure out if we want to keep innovating while taking care of the planet.

Market 🌐

Just think about how many new devices containing REEs it’s going to take to electrify the economy. All the increasing demand for sustainable and domestic sources of critical metals, particularly for applications in electric vehicles, wind turbines, and electronics.

The global market for magnet rare earth oxides is forecasted to increase threefold by 2030 and keep growing after that.

Other Key Players

Umicore 🇧🇪: A global materials technology and recycling group, specializing in the recycling of precious metals, rare earth elements, and other critical materials.

Noveon 🇺🇸: They both recycle rare earth magnets and manufacture new ones thanks to their patented magnet-to-magnet (M2M) recycling technology.

Founding Story 🦄

Cyclic Materials was co-founded in 2021 by Ahmad Ghahreman and Patrick William Nee. Ahmad is a serial entrepreneur with 15+ years in cleantech, 15+ patents and a Ph.D. in Materials Engineering from UBC. Patrick is a World Economic Forum Technology Pioneer and the previous founder of Universal Bio Mining.

They recognized the importance of recycling REEs from end-of-life products like magnets to reduce dependence on foreign sources, particularly China, and to mitigate the environmental impact of mining new materials.

Cyclic Materials developed proprietary technologies, including Mag-Cycle™ and REEPure™, to economically and sustainably recover REEs from waste materials.

They have since secured significant funding, including a $53 million Series B round, to expand the recycling infrastructure in North America, Europe, and Asia, and they have partnerships with giants like BMW.

Top Impact Stats 📈

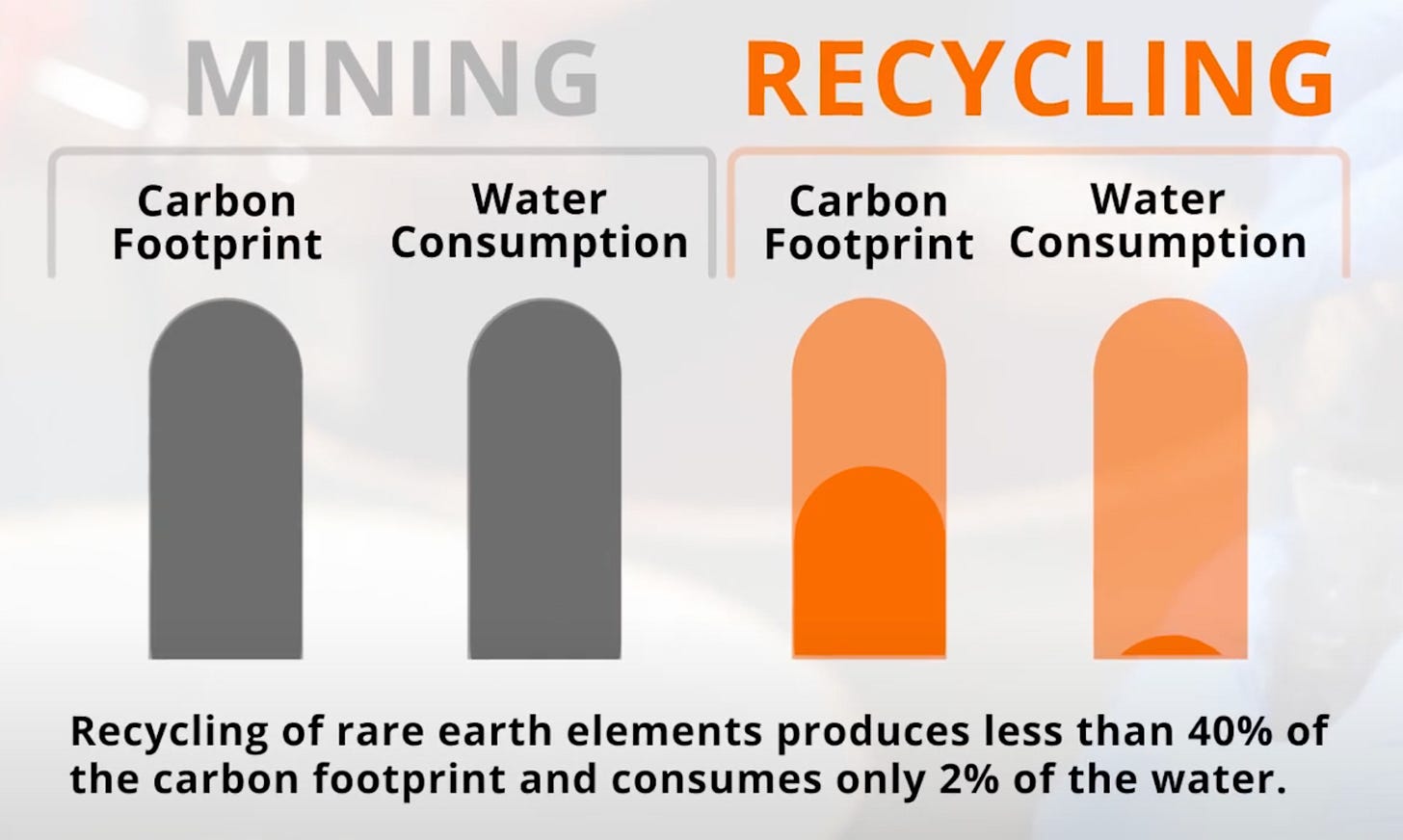

Recycled rare earth elements require as little as 36% of the CO₂ emissions to produce compared to newly mined material.

Their process consumes just 2% of the water that is typically used in rare earth mining and only 15% of the CO2 emissions compared to the traditional rare earth mining industry for producing the same amount of material.

Their recycling method generates negligible solid waste and does not contribute to radioactive pollution, which is a significant issue in conventional mining.

Whenever you’re ready, there are 2 ways I can help you:

Scale and optimize your climate business: I build automation systems for climate companies so they can free up time to scale their revenues and their climate impact.

Give visibility to your climate company: Get your company in front of an audience of thousands of climate players and enthusiasts by sponsoring newsletter issues and LinkedIn posts.

Thanks for reading today’s issue! If you liked it feel free to hit the ❤️ button and share it with someone who might like it too. See you next Saturday :)