Read time: 4 minutes

In this week’s issue you will learn about the different natural alternatives we have to making petroleum-based plastics: Bioplastics

“The average person is now ingesting 5 grams of plastic a week“ - The World Wide Fund for Nature

Top Bioplastics News 🗞️

Bioplastics aren’t the solution: We need viable pathways for recycling and composting bioplastics. Until then we won’t be able to make the most out of them.

Notpla wins the Earthshot Prize: They won in the “Build a Waste-Free World“ category. The prize was started by Prince William’s Royal Foundation in 2020 and is now the world’s most prestigious environmental prize.

Amazon invests in Genecis: The startup uses specialized bacteria to convert organic waste into biodegradable bioplastics that can be used to make everything from food packaging to clothing and textiles.

Let’s dive in 🧠

Petroleum-based plastics started booming in the 1950’s because they were easy and cheap to produce and very versatile.

Today there are 7 main types of plastic.

All of them have one thing in common: they contain carbon. That carbon comes from refined oil, thus making them is a polluting process.

But that’s not the main issue with plastics.

It’s the fact that they hang around in the ecosystem for hundreds of years. Pieces of plastic float around the ocean causing all sorts of problems such as poisoning marine life. Plastics break down into smaller and smaller pieces and become microplastics that we end up eating.

One potential solution to this issue are bioplastics.

What are they?

Plastics made out of “biomass” like potatoes, sugar cane or algae instead of petroleum-based sources.

Bio-plastics have a carbon footprint that’s 66% to 75% lower than that of petroleum-based plastics.

Sadly they make up less than 1% of the total market for plastics nowadays.

And here’s the trick, not all bio-plastics are biodegradable!

Actually around 45% of bioplastics produced today are not biodegradable. And that’s an issue because if they are not biodegradable they can still clog up the oceans and accumulate in marine animals.

Two very promising biodegradable bioplastic sources:

Algae:

Algae can be an awesome alternative to plastics. They are great because they are really oily, that’s why they can perform as well as petroleum-based plastics.

Even though most bioplastics use sugarcane or potato, algae grows faster, takes much less space and requires less water than land plants.

Some companies are now making flip-flops that fully biodegrade in a compost pile within six months. Even if they end up in the ocean, the algae-based flip flops will disappear in a year.

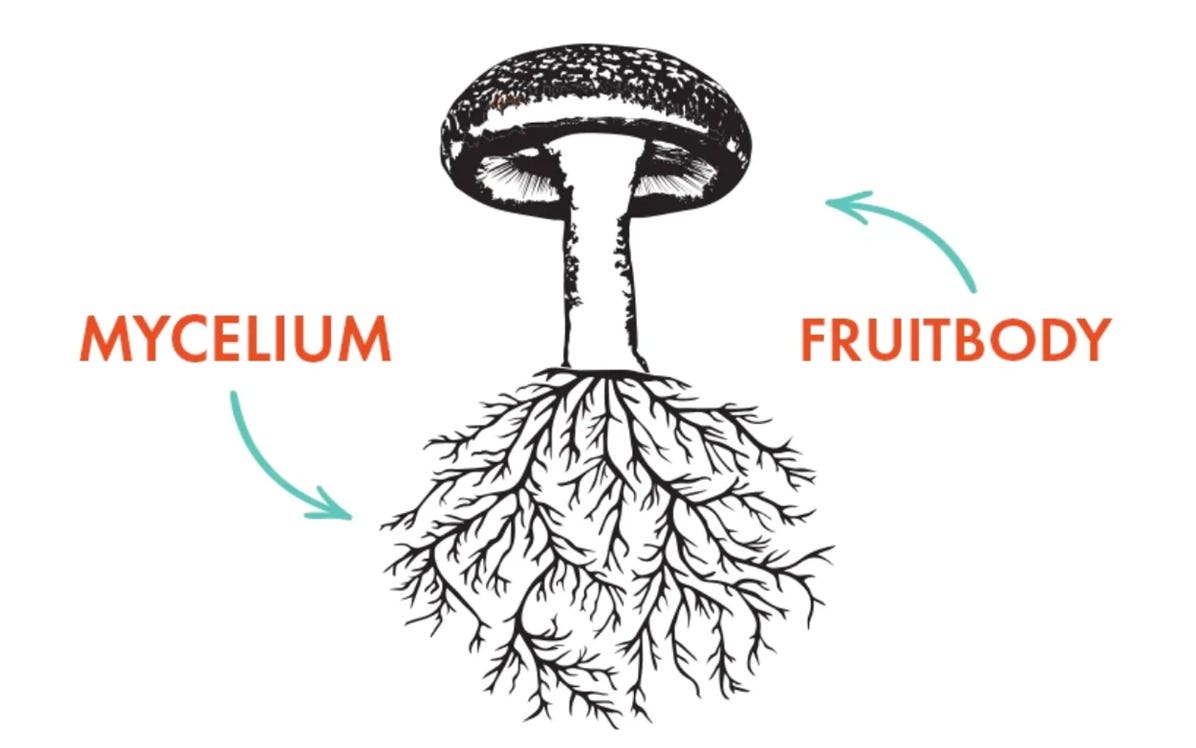

Mycelium:

Mycelium is another very promising alternative. This fancy word refers to the underground roots of fungi.

It grows very quickly, in about a week you can have enough to fill a mould.

Completely biodegradable.

90% CO2 equivalents reduction and only uses about 12% of the energy used by petroleum-based plastics.

The process: You mix agricultural waste such as hemp or wood with mycelium. This mixture is placed into moulds for whatever you’re trying to make.

Sure, bioplastics can help mitigate plastic pollution but by far the best way to fight plastic pollution is to use less of it, bio-based or not.

Cons

Resources: The plants grown for producing bioplastics can have a significant land, water and carbon footprint. To replace all plastic packaging with bioplastics we would need 54% of the world’s corn production.

Cost & Scale: Mycelium-based plastics can cost up to 3$ per pound vs 4¢ per pound for styrofoam (petroleum-based). Similar situations happen with other types. This happens because there is not enough mycelium and algae production. And it’s also difficult to scale the bioplastics production process.

Degradability: We have to make sure all bioplastics are biodegradable and that’s not easy since in some cases we lack the infrastructure to take them to a composting site or they are simply not biodegradable.

Top Bioplastics Companies 💰

Ecovative: The pioneers of mycelium-based products. Their materials are heat resistant, insulating, very strong, water-resistant, breathable and decompose in the soil within 35 days.

Bloom: They make EVA foam from algae they get from water bodies and water ways where there’s an excess of algae. They have cleaned over 1 billion litters of water this way.

Notpla: They use seaweed to replace plastic packaging. Ideal for instant out-of-home consumption. Their material is biodegradable and home-compostable.

Also take a look at Munjoi (shoes and sandals made out of algae, sugarcane, algae and cotton) and Algenesis (foams and more solid plastics made out of algae).

❗Extreme knowledge area❗

Detailed report: This analysis from the awesome CTVC newsletter covers all the aspects about bioplastics and the market behind it.

Algae and mycelium: If you want a more detailed explanation of the algae and mycelium bioplastics industries take a look at these two videos.

That’s it for today, 1 climate tech topic in under 5 minutes.

Next up… Fire tech! 🤯

If you enjoyed today’s issue, the best compliment you could pay me would be to share it with one person who you think would benefit from it :)